We Give the Best Services

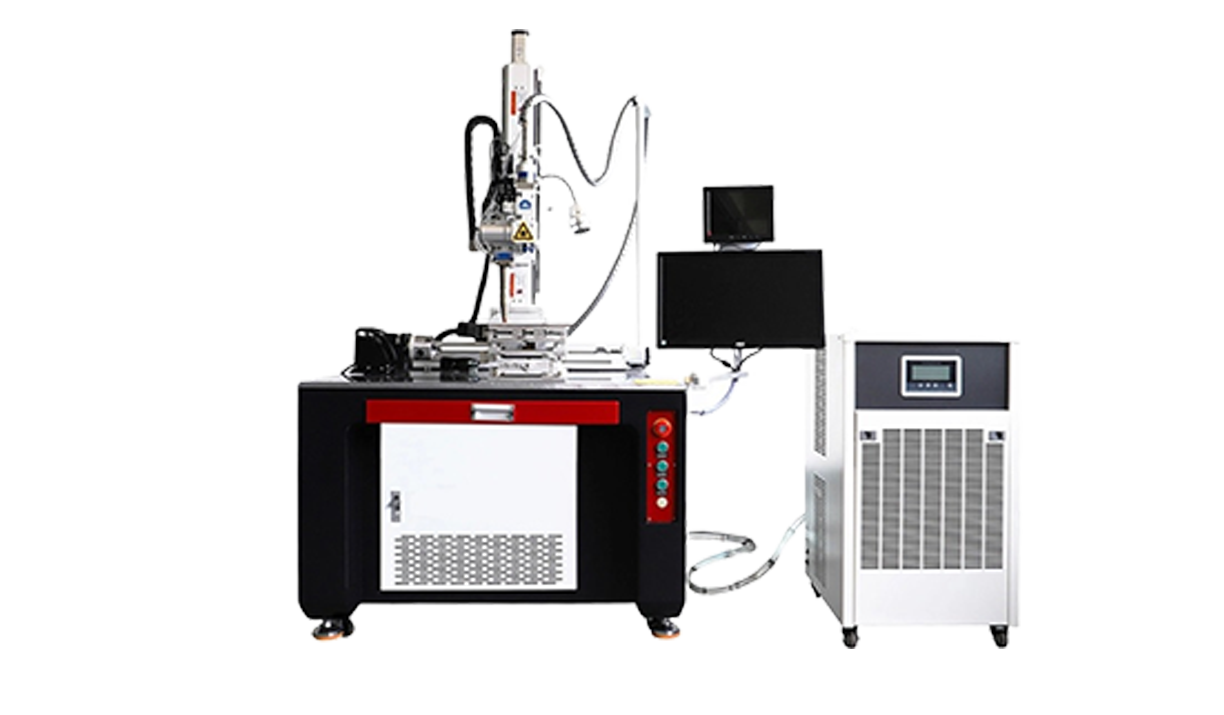

Jewellery Laser Welding Machines are provided with many important as well as simple facets of laser welding technology. They will cope with surfaces with various work pieces. The thermal conduction process of the Jewellery Laser Welding Machines enables them to control the width, peak power and energy of the machine. They have many of these unique features and are used solely for the processing of precious jewellery as well as for the welding of precision parts. The machines have various welding effects that make it easier to use the seal cavity.

Why You Must Buy?

Save Man Power Time

Easy to Operate Machine

24x7 Hours non Stop Working

Working on Single Phase

No Risk Jewellery Damage

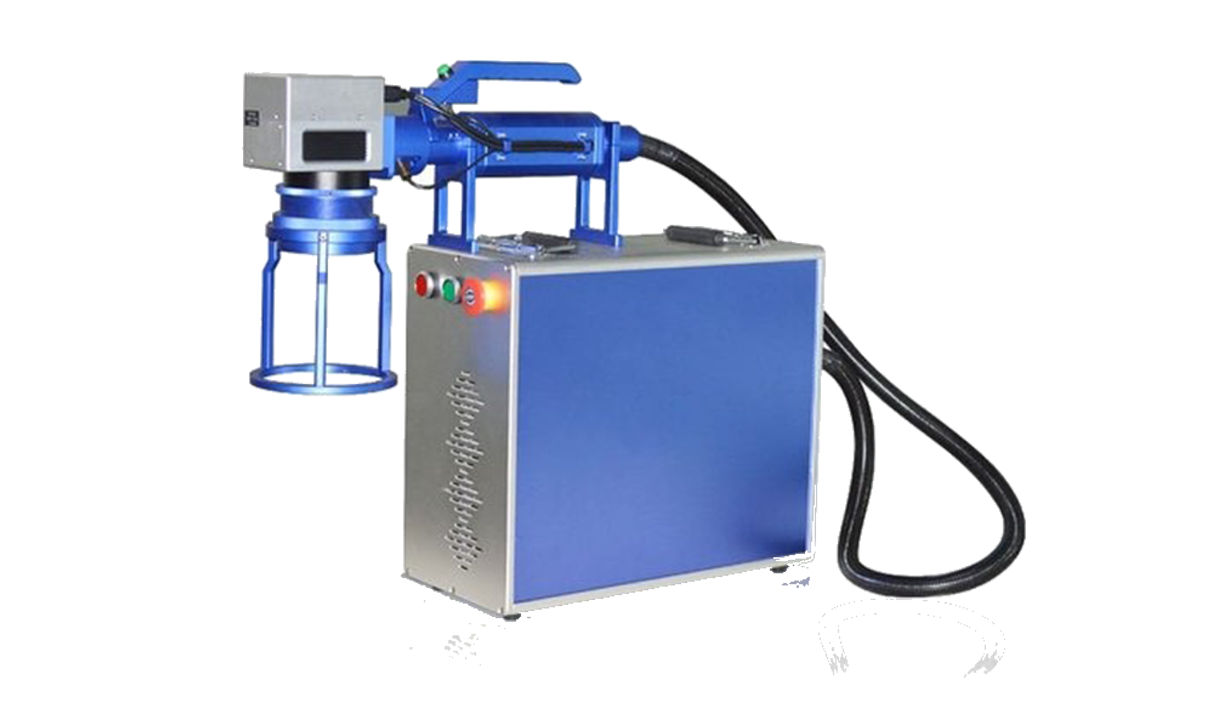

Forget inkjet, pad printing, stickers

Creative design for customers

Brand logo printing on non metals

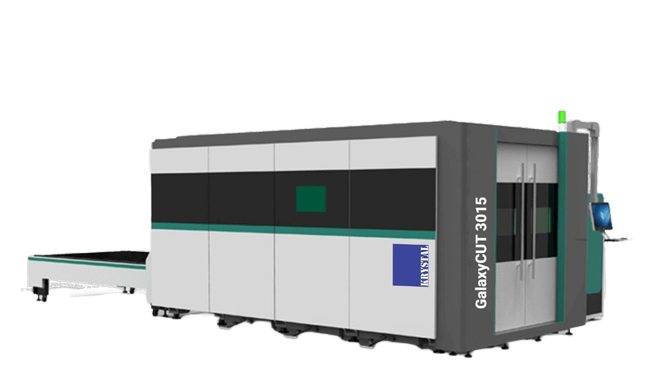

Sharp & fast precise cutting

Better solution than pad printing, inkjet , sticker & manual hand cutting

Technical Specifications

Material

Features

Applications

| Sr. No. | Parameters | Details |

| 1 | Laser Type | ND : YAG |

| 2 | Laser Power | 200 Watt (Optional 150,300,400) |

| 3 | Single Pulse Max. Energy | 90 J & 125 J |

| 4 | Laser Wavelength | 1064 ± 4nm |

| 5 | Laser welding Depth | 0.1-3MM |

| 6 | Laser Pulse Width | 0.1-20MS |

| 7 | Combo Laser Welding Freq. | 0-50Hz |

| 8 | Spot Size Adjustable | 0.2–3MM |

| 9 | Machine Power Consumption | >6KW |

| 10 | Laser Positioning | Red Pointer |

| 11 | Electrical Requirement | AC 220v–50Hz |

| 12 | Supporting Format | PLT, DXF, AI, JPG, BMP, SVG, BOT, GBR, DST, NC, JPEG, GIF, PNG, TIF, TXT, DOCX, XLSX |

| 13 | Observing System | 10X Microscope or High definition |